Feb 16, 2026 05:31 AM

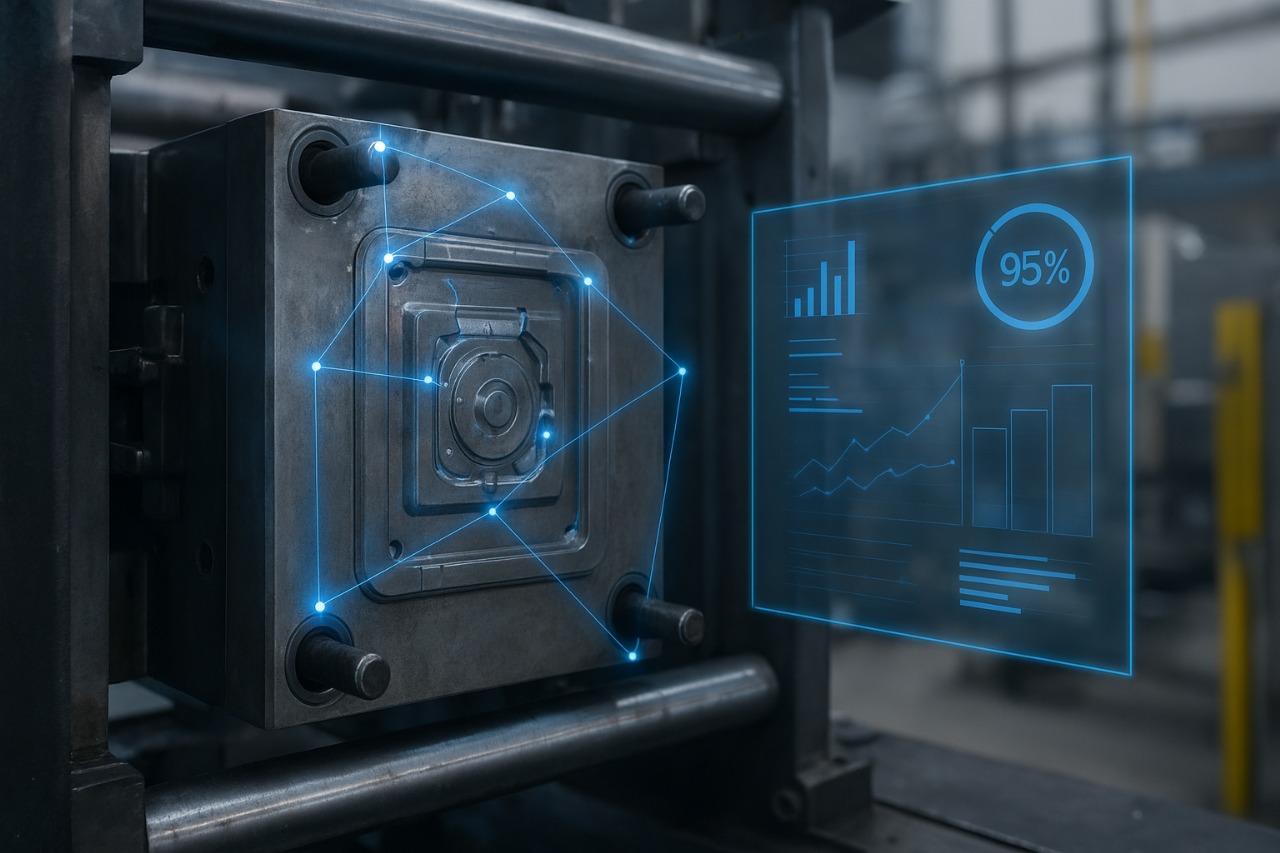

From Reactive to Predictive: Extending Mold Lifecycles with AI in Packaging Operations

test-In packaging production, few assets are as capital-intensive and as chronically under-managed as molds. Whether it's injection molding for bottle caps or blow molding for bottles, every packaging format depends on molds performing at their best. Yet, across industries, mold-related inefficiencies continue to erode productivity, inflate costs, and delay time-to-market.

It's time to rethink how we manage molds, not just as tools, but as strategic assets with full lifecycle value.

The Hidden Cost of Mold Mismanagement

When a mold goes down, production doesn't just stall, it often catches teams off guard. The news of a stoppage comes as a surprise, leading to abrupt halts in manufacturing and long lead times for recovery and product replenishment. What's often overlooked is why it happens. Most companies treat mold management reactively: waiting for issues to emerge, relying on outdated records, and scrambling across team members for answers.

Some key challenges include:

- Lack of lifecycle visibility: Most organizations don't track mold condition, usage history, or maintenance timelines in one place.

- Data fragmentation: Specs, trial reports, and approval logs often sit across emails, PDFs, or individual hard drives.

- Trial & validation delays: New packaging trials get stuck because data from previous projects isn't searchable or accessible.

- Ownership confusion: Between brand owners, converters, and mold suppliers, accountability becomes diluted, especially for shared molds or multi-site operations.

- Downtime & OSA (On-Shelf-Availability): Unplanned downtime is costly, and without preventive insights, molds are often underutilized or sidelined without clear reasoning.

???? Did you know? Based on industry discussions and internal assessments, over 50% of packaging trials miss their initial timeline. This is often due to preventable issues in mold readiness, data gaps, or unclear ownership.

From Chaos to Control: Building a Better Mold Management System

Leading organizations are shifting from a reactive model to a proactive, digital-first mold lifecycle management system. This means managing molds not as isolated assets, but as part of an integrated packaging ecosystem.

Here's what that shift includes:

? All Digitally Enabled—at the Click of a Button

Every insight, action, and alert is accessible through an intuitive interface—bringing control and clarity to mold operations in real time.

? Centralized Digital Repository

A single source of truth for all data, from mold specifications and performance history to maintenance logs and usage frequency.

? Defined Lifecycle Stages

Molds are tagged by lifecycle status, Design, Trials, Commissioning, Production, or Retirement, so teams make informed decisions faster.

? Cross-Stakeholder Collaboration

Whether it's brand managers, mold makers, or operations leads, everyone should be able to view the same real-time data through a shared dashboard.

? Preventive Maintenance Triggers

Use digital mold tracking to set alerts based on cycle counts, time, or performance dips, enabling predictive rather than reactive maintenance.

? Audit Trails & Accountability

Detailed histories of change requests, trials, repairs, and ownership help improve transparency, reduce errors, and aid compliance.

Why This Matters More Than Ever

In today's fast-evolving packaging industry, where SKUs are increasing, validation cycles are tightening, and sustainability pressures are rising, mold downtime isn't just an operational problem, it's a business risk.

Key statistics:

- In high-throughput packaging lines, unplanned mold-related downtime can cost anywhere from $2,000 to over $10,000 per hour, depending on the product type, line speed, and plant complexity.

- According to industry estimates, digital tooling dashboards can reduce rework and validation delays by up to 30% by centralizing mold specifications, performance history, and trial outcomes. This becomes especially impactful in multi-SKU or seasonal packaging formats where speed-to-market is critical.

- In multi-plant environments, centralized mold visibility has been shown to reduce redundant mold investments and improve asset utilization by 20-25%, enabling smarter capex allocation and lowering total tooling spend.

Sources: Industry insights derived from Deloitte, IndustryWeek, GE Digital case studies, and Packfora tooling workshops. Data points are representative and may vary by plant size and process.

Digital Tools are Changing the Game

As digital mold management platforms gain ground, organizations are starting to treat molds not as static assets, but as dynamic, evolving tools with measurable value across their lifecycle.

These platforms are helping packaging and operations teams to:

- Gain real-time visibility of mold condition, usage, and location across plants and geographies

- Accelerate packaging trials by eliminating redundant steps and unlocking past validation data

- Drive alignment across functions—ensuring everyone from procurement to production is working off the same mold readiness status

- Simplify onboarding through structured, searchable documentation that reduces reliance on tribal knowledge

Leaders Take: “We don't waste time anymore chasing trial data or guessing mold status. It's all one click away. More organized and easily accessible. And that's changed how fast we move.”

— Head of Packaging Operations, Global F&B Company

Conclusion: What's Your Mold Strategy?

A strategic mold lifecycle plan, powered by smart dashboards and collaborative access, can unlock productivity, sustainability, and speed at scale.

Ask yourself:

Are your molds enabling your business or giving you sleepless nights?